The Nikon D80 instruction manual provides essential guidance for operating this 10.2-megapixel DSLR, introduced in 2006. It covers features, troubleshooting, and customization, ensuring optimal camera performance.

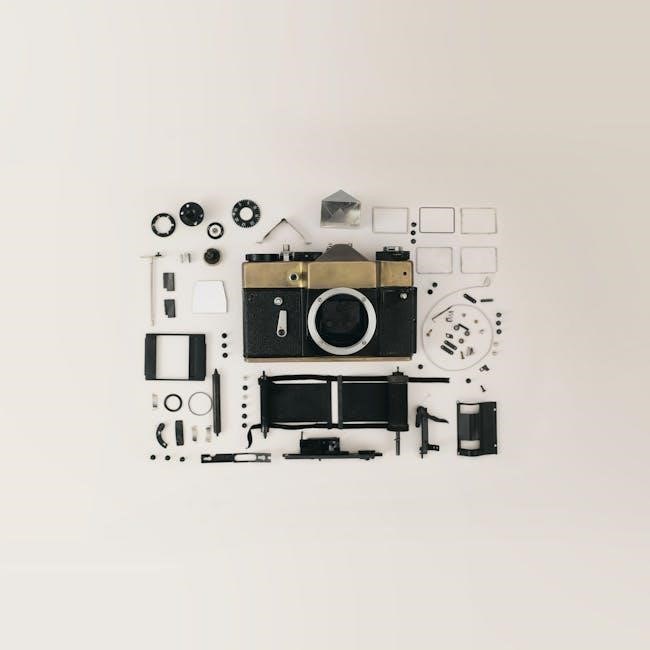

1.1 Key Features of the Nikon D80

The Nikon D80 boasts a 10.2-megapixel CCD sensor, delivering high-resolution images. It features a 2.5-inch LCD display for clear image preview and review. The camera supports various shooting modes, including manual, aperture priority, and shutter priority. Additional features include a built-in flash, ISO sensitivity up to 1600, and compatibility with Nikon F-mount lenses. These capabilities make the D80 a versatile and powerful tool for photographers seeking precise control and exceptional image quality.

1.2 Importance of the Instruction Manual

The Nikon D80 instruction manual is a comprehensive guide that helps users understand and master the camera’s features and functions. It provides detailed instructions for optimal camera setup, shooting modes, and customization options. The manual also includes troubleshooting tips and maintenance advice, ensuring users can resolve issues quickly. By following the manual, photographers can unlock the full potential of the D80, enhancing their creativity and technical skills for capturing high-quality images.

Where to Find the Nikon D80 Instruction Manual

The Nikon D80 instruction manual can be found on Nikon’s official website or third-party resources like ManualsLib, ensuring easy access for users seeking guidance.

2.1 Official Nikon Website

The official Nikon website offers a dedicated section for the D80 manual. Users can easily download the PDF version, ensuring authenticity and reliability. The manual is free and available in multiple languages, including English, making it accessible worldwide. Nikon’s website guarantees the most up-to-date and accurate information, providing a trustable source for D80 users to enhance their photography experience effectively.

2.2 Third-Party Resources and ManualsLib

Beyond Nikon’s official site, third-party platforms like ManualsLib provide free access to the D80 manual. These resources often include user-submitted guides and FAQs. ManualsLib, in particular, offers a comprehensive PDF version of the D80 manual, rated highly by users. While convenient, ensure downloads are from trusted sources to avoid security risks. These platforms are invaluable for those seeking additional perspectives or troubleshooting tips beyond the official documentation.

Essential Tips from the Nikon D80 User Manual

The manual offers practical guidance for optimizing camera use, including mastering focus techniques, customizing settings, and troubleshooting common issues to enhance photography skills and user proficiency effectively.

3.1 Mastering Focus: Manual and Autofocus Techniques

Mastery of focus is crucial for sharp images. The Nikon D80 offers Single AF, Continuous AF, and Manual Focus modes. Use the AF-mode button to switch modes. In Manual Focus, use the focus ring for precise control. For autofocus, select the right AF area mode (e.g., Dynamic or Single Servo) to track subjects effectively. Utilize the focus lock technique to recompose shots without refocusing. Experiment with custom settings to optimize focus accuracy for various photography scenarios.

3.2 Optimizing Camera Settings for Best Results

To achieve optimal results, adjust camera settings based on lighting and subject conditions. Use Program AE for automatic adjustments, or switch to Shutter or Aperture Priority for more control; In Manual mode, set aperture and shutter speed using the front and rear dials. Adjust ISO for low-light situations and fine-tune white balance for accurate colors. Experiment with AF modes and custom settings to enhance sharpness, contrast, and overall image quality for professional-grade photography.

Nikon D80 Specifications and Main Features

The Nikon D80 features a 10.2-megapixel CCD sensor, 2.5-inch LCD display, and compatibility with Nikon F-mount lenses. It supports ISO 100-1600 and offers 3D Color Matrix Metering for precise exposure control.

4.1 10.2 Megapixel CCD Sensor

The Nikon D80 is equipped with a 10.2-megapixel CCD sensor, delivering high-resolution images with exceptional detail and color accuracy. This sensor captures vivid colors and sharp contrasts, even in challenging lighting conditions. Its pixel count ensures excellent image quality, making it ideal for both professional and amateur photographers. The CCD sensor’s performance is further enhanced by Nikon’s advanced image processing technology, providing clean and noise-free results across a wide ISO range.

4.2 2.5-Inch LCD Display

The Nikon D80 features a 2.5-inch LCD display, offering a clear and detailed view of images and settings. With a resolution of 230,000 pixels, it provides vivid previews and playback. The screen is bright and responsive, making it easy to navigate menus and review photos. This LCD display is a valuable tool for composing shots, adjusting settings, and ensuring optimal results, enhancing the overall user experience for photographers of all levels.

Advanced Settings and Customization

The Nikon D80 offers advanced customization options, enabling users to tailor camera settings to their preferences, with the LCD display aiding in intuitive setup navigation for enhanced performance.

5.1 Understanding Aperture, Shutter Speed, and ISO

The manual explains aperture, shutter speed, and ISO as fundamental exposure controls. Aperture regulates light entry, shutter speed captures motion, and ISO adjusts sensitivity. Balancing these elements is crucial for achieving desired effects, from sharp images to artistic blur. The D80’s manual mode allows users to independently adjust these settings, providing creative control and precision in various lighting conditions.

5.2 Custom Settings and Menu Functions

The Nikon D80 manual details extensive customization options, allowing users to tailor camera settings to their preferences. The menu system provides access to advanced functions, such as button assignments and shooting preferences. Custom settings enable personalized control over features like autofocus modes and metering patterns. Dual-function buttons, such as the thumbnail button (zoom out/ISO) and protect button (help/white balance), enhance operational efficiency. Mastering these settings ensures streamlined workflows and improved shooting experiences.

Troubleshooting Common Issues

The Nikon D80 manual addresses common issues like error messages and shutter problems, offering solutions to ensure smooth camera operation and minimize downtime for photographers.

6.1 Camera Error Messages and Solutions

The Nikon D80 manual provides detailed explanations and solutions for common error messages. Issues like “Err” or “CARD FULL” are addressed, offering step-by-step fixes. Solutions include formatting memory cards, cleaning the sensor, and checking for firmware updates. The manual also covers aperture and shutter-related errors, ensuring photographers can quickly resolve problems and continue shooting without interruption. This section is crucial for maintaining optimal camera functionality and user confidence.

6.2 Shutter and Aperture Control Unit Maintenance

Regular maintenance of the shutter and aperture control units is crucial for the Nikon D80’s performance. The manual recommends cleaning the sensor with a blower and soft cloth to remove dust. Avoid harsh chemicals and ensure all components are dry before reassembly. Proper maintenance ensures precise aperture control and shutter operation, extending the camera’s lifespan. Always use Nikon-approved cleaning tools and follow the manual’s guidelines for optimal results and to prevent damage.

Accessories for the Nikon D80

The Nikon D80 supports a range of accessories, including the MB-D80 battery pack, which extends shooting capabilities and enhances ergonomics. Compatible lenses and flash units further expand creative options.

7.1 MB-D80 Multi-Power Battery Pack

The MB-D80 Multi-Power Battery Pack enhances the Nikon D80’s functionality, offering extended battery life and improved ergonomics. It supports EN-EL3e lithium-ion batteries or six AA batteries, ensuring uninterrupted shooting. The pack also features a vertical shutter release button for easier handling in portrait orientation, making it ideal for professionals and enthusiasts seeking durability and comfort during long photography sessions.

7.2 Compatible Lenses and Other Accessories

The Nikon D80 is compatible with a wide range of Nikon F-mount lenses, offering versatility for various photography needs. From wide-angle to telephoto and macro lenses, users can explore different perspectives. Additionally, the camera supports external flash units, remote controls, and other accessories, enhancing functionality and personalization. These accessories ensure photographers can tailor their setup to achieve optimal results in diverse shooting scenarios.

The Nikon D80 instruction manual is a vital resource for unlocking the camera’s full potential. It guides users through key features, troubleshooting, and advanced settings, ensuring mastery of this iconic DSLR.

8.1 Final Thoughts on the Nikon D80 Manual

The Nikon D80 manual is an indispensable guide, offering comprehensive insights into camera operations. It covers essential features, troubleshooting, and customization, helping photographers master the D80. With detailed explanations and practical tips, it ensures users optimize their camera’s performance and achieve exceptional results. This manual remains a crucial companion, enhancing both technical understanding and creative expression, making it a valuable resource for photographers of all skill levels.

Downloading the Nikon D80 Manual

Download the Nikon D80 manual from Nikon’s official website or trusted third-party sources like ManualsLib. Ensure authenticity and safety by using official links for the PDF.

9.1 Direct Links and Download Instructions

Visit Nikon’s official website or trusted platforms like ManualsLib to download the Nikon D80 manual. Ensure you select the correct language and version. Click on the provided PDF links, verify the file size and language, then save or print the manual for easy reference. Always use secure, official sources to avoid corrupted files.