Guide rollers are mechanical components designed to guide, align, or support moving parts in various industrial applications, ensuring smooth operation and precise linear motion.

1.1 Definition and Purpose

Guide rollers are cylindrical components designed to guide, support, or align moving parts in machinery or systems. Their primary purpose is to ensure smooth, precise motion by reducing friction and wear. Typically mounted in fixed or adjustable positions, they are essential for maintaining operational efficiency in various industrial and mechanical applications, including conveyors, material handling, and manufacturing equipment.

1.2 Brief History and Evolution

Guide rollers have evolved significantly since their inception in early industrial machinery. Initially simple cylindrical components, they were made from basic metals and served limited purposes. Over time, advancements in materials and precision engineering led to more durable and adaptable designs. Modern guide rollers now incorporate bearings, adjustable mounts, and specialized materials like stainless steel and plastics, enabling their use in diverse applications with enhanced performance and longevity.

Types of Guide Rollers

Guide rollers come in various types, including fixed, adjustable, and precision models, each designed for specific applications, ensuring versatility in industrial and mechanical systems.

2.1 Fixed Guide Rollers

Fixed guide rollers are stationary components designed to provide consistent alignment and support for moving parts in industrial machinery. They are typically mounted in permanent positions and do not allow for adjustment, making them ideal for applications requiring precise and unchanging guidance. These rollers are often used in conveyor systems, material handling equipment, and other industrial setups where consistent alignment is crucial. Their simple design ensures durability and reliability, making them a cost-effective solution for many manufacturing environments. Fixed guide rollers are commonly constructed from durable materials such as steel or PVC to withstand heavy-duty operations, ensuring smooth and consistent performance over time.

2.2 Adjustable Guide Rollers

Adjustable guide rollers offer flexibility in alignment and positioning, allowing for precise adjustments to accommodate varying tolerances or changing operational needs. They are commonly used in industrial machinery and conveyor systems where adaptability is essential. These rollers typically feature mechanisms such as linear bearings or adjustment screws, enabling fine-tuning of their position to ensure smooth and consistent performance. Their versatility makes them ideal for applications requiring frequent modifications or adjustments, ensuring optimal functionality across different operating conditions.

2.3 Precision Guide Rollers

Precision guide rollers are engineered for high-accuracy applications, offering minimal friction and exceptional stability. They are designed with tight tolerances and advanced materials, such as stainless steel or high-performance polymers, to ensure consistent performance in demanding environments. These rollers are often used in CNC machines, robotics, and precision conveyor systems, where exact positioning and smooth motion are critical. Their durability and resistance to wear make them ideal for applications requiring consistent, repeatable results over extended periods.

Materials and Construction

Guide rollers are typically made from durable materials such as stainless steel, aluminum, or high-performance polymers, ensuring longevity and resistance to wear in various industrial applications.

3.1 Common Materials Used

Guide rollers are often constructed from high-strength materials like stainless steel, aluminum, or durable polymers to ensure longevity. Stainless steel is favored for its corrosion resistance, while aluminum offers lightweight durability. Polymers, such as nylon or UHMW, provide excellent wear resistance and quiet operation. These materials are chosen for their ability to withstand heavy loads and harsh environments, making them ideal for industrial applications requiring reliability and performance.

3.2 Bearing Types and Designs

Guide rollers often incorporate ball bearings, roller bearings, or needle bearings to facilitate smooth motion. Ball bearings are ideal for light to medium loads, while roller bearings handle heavier loads and shocks. Needle bearings are compact and suitable for tight spaces. Bearings are typically sealed or open, depending on the application, and may feature lubrication options to enhance durability and performance in various industrial environments.

Applications and Uses

Guide rollers are essential in industrial machinery, conveyor systems, and material handling equipment, ensuring smooth operation and precise alignment in various manufacturing and logistics processes.

4.1 Industrial Machinery

Guide rollers play a crucial role in industrial machinery by ensuring precise alignment and smooth movement of components. They are widely used in manufacturing processes, automotive assembly lines, and heavy-duty equipment. These rollers minimize wear and tear, reduce friction, and enhance operational efficiency. Their ability to handle heavy loads and withstand harsh environments makes them indispensable in maintaining production line consistency and overall machine performance.

4.2 Conveyor Systems

Guide rollers are essential in conveyor systems, ensuring products move smoothly and remain aligned. They are used in various conveyor types, including belt, chain, and roller conveyors. By reducing friction and preventing misalignment, guide rollers enhance efficiency, minimize wear, and protect products from damage. Their durability and load-bearing capacity make them critical for maintaining continuous operation in industries like logistics, packaging, and manufacturing, where conveyor systems are integral to workflows.

4.3 Material Handling Equipment

Guide rollers play a crucial role in material handling equipment, ensuring smooth and efficient movement of goods. They are widely used in systems like forklifts, cranes, and automated storage solutions. By guiding and supporting heavy loads, these rollers reduce friction and prevent misalignment, enhancing operational efficiency. Their durability and load-bearing capacity make them indispensable in industries where precise and reliable material handling is essential for maintaining productivity and safety standards.

Advantages of Guide Rollers

Guide rollers offer improved accuracy, reduced wear and tear, and enhanced operational efficiency, making them a crucial component in various industrial and mechanical systems.

5.1 Improved Accuracy

Guide rollers enhance precision by maintaining consistent alignment and smooth movement in industrial systems. Their stable support reduces vibrations and misguidance, ensuring accurate positioning and reliable performance in critical applications.

5.2 Reduced Wear and Tear

Guide rollers minimize wear and tear by ensuring smooth, consistent movement and proper alignment of moving parts. Their durable materials and precise engineering reduce friction, preventing excessive stress on components. This results in extended equipment lifespan and lower maintenance costs, making them essential for long-term operational efficiency in industrial settings.

Installation and Maintenance

Proper installation ensures alignment and secure fastening, while regular maintenance involves lubrication and inspection to maintain optimal performance and extend service life.

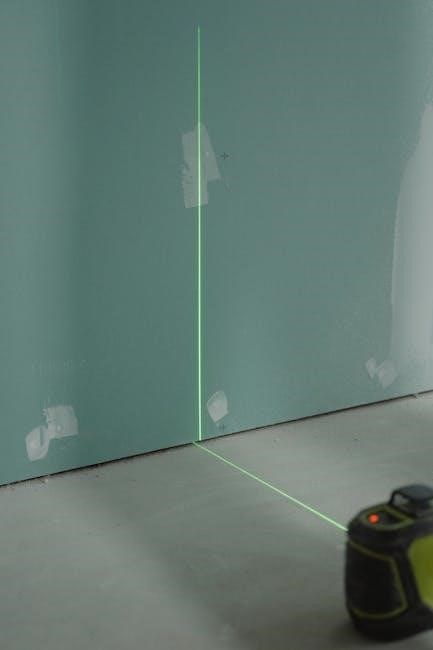

6.1 Proper Installation Techniques

Proper installation of guide rollers involves aligning them accurately and securing them firmly to prevent misalignment. Use precision tools to ensure correct positioning and tighten fasteners gradually to avoid uneven stress. Refer to manufacturer guidelines for specific torque values and mounting hole dimensions. Proper alignment ensures smooth operation, reduces wear, and extends the lifespan of the rollers and associated machinery. Always double-check the installation for stability before operation.

6.2 Regular Maintenance Practices

Regular maintenance of guide rollers involves cleaning to remove dirt and debris, which can cause wear. Lubrication is essential to reduce friction and prevent corrosion. Inspect rollers for signs of wear, misalignment, or damage. Replace worn-out components promptly to maintain performance. Check fasteners for tightness and ensure proper alignment. Schedule periodic inspections and follow manufacturer guidelines for optimal upkeep. Proper maintenance extends lifespan and ensures smooth, reliable operation of guide rollers in various applications.

Technical Specifications

Technical specifications for guide rollers include load capacity, dimensional tolerances, and mounting options. These details ensure compatibility and optimal performance in various industrial applications. Materials and designs vary.

7.1 Load Capacity and Tolerances

Load capacity specifies the maximum weight a guide roller can support without deformation. Tolerances define acceptable dimensional deviations, ensuring precise alignment and fitment. These specifications vary by design, material, and application, with tighter tolerances used in high-precision systems. Proper selection ensures optimal performance, reliability, and longevity in industrial machinery and conveyor systems. Understanding these factors is critical for choosing the right guide roller for specific operational demands and environments.

7.2 Mounting Options and Dimensions

Guide rollers are available in various mounting options, including through-hole, threaded, and quick-release designs, ensuring flexibility in installation. Standard dimensions are predefined for common applications, while custom sizes can be tailored to specific needs. Proper alignment and fitment are crucial to ensure optimal performance and longevity. Engineers often specify mounting styles and dimensions based on load requirements, operational conditions, and system design constraints to achieve precise integration and functionality.

Safety Considerations

Safety considerations for guide rollers include proper handling, secure installation, and regular inspections to prevent accidents. Ensuring correct alignment and load distribution is crucial. Always follow manufacturer guidelines to minimize hazards and maintain operational safety;

8.1 Operating Safety Tips

Operating guide rollers safely requires proper installation, regular lubrication, and monitoring of wear. Always follow load capacity guidelines to avoid overload. Ensure alignment is correct to prevent uneven stress. Use protective gear when handling rollers, and avoid over-tightening during installation. Regular inspections can help identify potential issues before they cause downtime or accidents. Proper training and adherence to manufacturer guidelines are essential for safe operation.

8.2 Hazard Prevention Measures

To prevent hazards, ensure proper installation and alignment of guide rollers. Regularly inspect for wear or misalignment, and lubricate as needed. Avoid overloading beyond rated capacities, as this can cause failure. Use protective equipment when handling rollers, and ensure guarding is in place to prevent contact with moving parts. Implement emergency stop systems and provide training on safe operating practices. Always follow manufacturer guidelines to minimize risks;

Case Studies and Examples

Guide rollers are essential in manufacturing, enabling precise material alignment. Real-world applications include conveyor systems, printing presses, and robotic assembly lines, ensuring smooth and efficient operations.

9.1 Real-World Applications

Guide rollers are widely used in various industries to ensure smooth and precise movement of components. In conveyor systems, they align products for packaging, reducing wear and tear. In printing presses, they guide paper rolls accurately, maintaining print quality. Additionally, guide rollers are integral in robotic assembly lines, enabling precise part placement and enhancing overall production efficiency. Their versatility makes them indispensable in modern manufacturing processes.

Guide rollers are essential components in modern machinery, ensuring smooth operation and precision. Their versatility and durability make them indispensable in various industrial applications, enhancing efficiency and performance.

10.1 Summary of Key Points

Guide rollers are versatile components used across industries to ensure smooth motion and alignment. They enhance precision, reduce wear, and improve efficiency in machinery. Available in various types and materials, they cater to different applications, from industrial to material handling. Proper installation and maintenance are crucial for optimal performance. Their benefits include improved accuracy and durability, making them essential for modern industrial operations. Understanding their applications and care ensures long-term functionality and reliability.